Course Overview:

Delivery Options:

Length: 4-days

Percent Hands-on: 50%

Description: This course introduces students to the core fundamentals involved with modern industrial instrumentation, measurement, calibration, and controls. This course places heavy emphasis on the topics that are often misunderstood in industry and which cause many of the maintenance, troubleshooting, and plant performance problems.

This course is useful for anyone from a mechanical technician or operator needing to better understand the instrumentation associated with their systems up to senior instrumentation technicians and engineers. The topics presented are based on decades of expert observations of the problems and mistakes made throughout the instrumentation and controls fields.

Detailed Description:

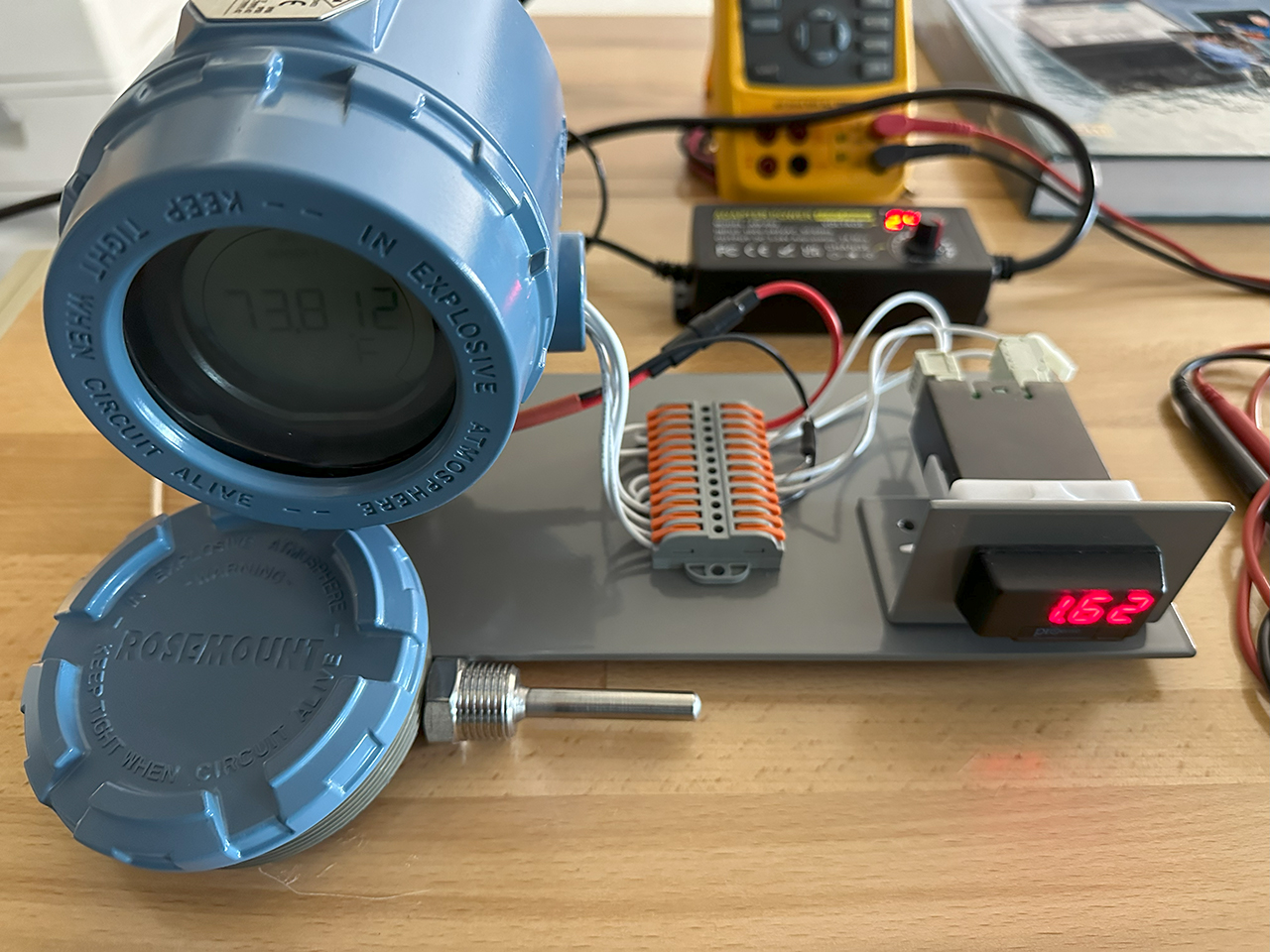

The first part of this course will utilize Rosemount® Smart transmitters connected to an analog input loops. Students will troubleshoot and perform various maintenance tasks such as calibrations, verifications, and proof testing, on typical (Rosemount) transmitters in typical instrument loop configurations.

The ‘big picture’ objectives of typical Instrumentation systems will be the center point of discussions and training, to include process safety, process control, and regulatory compliance/reporting. This course covers the core concepts very effectively and reinforces material with excellent hands-on exercises. This course is designed to produce long term results.

Students will work with a variety of equipment, including Rosemount transmitters, RTD & Thermocouples, Multi-function calibrators, Fluke 789 Process Meters, Fluke 724 Temperature Calibrators, HART Communicators, and more.

This course will cover all of the underlying concepts that even many senior instrumentation technicians don’t fully understand, and which often cause mistakes and problems in the field.

Course Outcomes:

- Understand the 4-20mA control loop and how to effectively test and troubleshoot analog IO problems.

- Understand the operation of modern SMART transmitters and gain familiarity with the common functionality, mistakes, and misconceptions associated with them.

- Understand instrument and transmitter calibration concepts, including common errors, best practices for calibration programs, etc.

- Learn to utilize common instrumentation test and calibration equipment such as process meters, calibrators, and HART communicators.

- Understand signal noise and the importance of proper signal filtering (damping) and the safety and control performance problems that incorrect filtering can cause.

- Understand typical instrumentation calibration & maintenance programs and common mistakes and problems.

- Understand the operation and concepts behind typical control valves, actuators, and positioners.

- Understand basics of feedback control and typical methods used (analog, on/off control, integrating/ramping control, PWM, etc.)

- Become familiar with the operation of common types of controllers and control systems used within the instrumentation field and with the typical hierarchy of plant control & shutdown systems.

- Learn the basic concepts behind PID controls and be able to recognize common field-induced problems in process control performance.

- Understand how to troubleshoot each of the following types of common instrumentation performance problem causes (deadtime and lag, noise, actuators and control elements, nonlinearity, operating outside effective range of control, reset windup/process saturation, etc.)

- Become familiar with common process control strategies and methods.

- Understand potential process safety issues and mistakes when working with instrumentation.

- Gain basic familiarity with Safety Instrumented System (SIS) testing, per IEC 61511.

Hands-On Exercises:

Set up, configure, test, and calibrate typical smart transmitters using modern calibration equipment and HART communicators. Some of the specific lab exercises covered include:

- 4-20mA loop concepts and troubleshooting

- Smart transmitter functionality (how they are different from old analog transmitters and why they must be treated very differently).

- Transmitter damping labs

- RTD testing, calibration, and mistakes lab

- Thermocouple testing, calibration, and mistakes lab

- Smart transmitter configuration details (including damping, AI trim, AO trim, test outputs, fault settings, alerts/alarms, etc.

- Calibrating transmitters (and common mistakes and problems, and best practices)

- Understanding instrumentation accuracy, errors, tolerances, etc.

- Troubleshooting 4-20mA loops, transmitters, analog IO, scaling problems, etc.

- Level DP troubleshooting and configuration demos

- Flow DP troubleshooting and misconceptions demos

- Simulated control loops setup, tuning, and troubleshooting demos

- Analyze, optimize, and troubleshoot simulated control system performance.

- Perform typical Safety Instrumented Systems proof testing for a SIL-rated instrument function (as applicable)

Each student attending will be given a certificate of completion upon completing the course.

This is an incredibly valuable course to those seeking to learn and understand the key issues and concepts in the I&C field. Students and managers rate this course very highly and tell us the impact of the training in the field is outstanding and a great ROI.

Related Courses:

|

Dates |

Event Details |

Course Title |

Cost |

Register |

|

Nov 4-7, 2024 4-days |

(Click link above for event details) |

$1995 |

REGISTRATION CLOSED (Email Us for Waiting List) |

|

|

Nov 9-10 & Nov 16-17, 2024 4-days (4 días) |

(Click link above for event details) |

Basic Electrical Troubleshooting (Spanish) |

$1995 |

REGISTRATION CLOSED (Email Us for Waiting List) |

|

Nov 11-14, 2024 4-days |

(Click link above for event details) |

$2495 |

Register | |

|

Nov 18-21, 2024 4-days |

(Click link above for event details) |

$2495 |

Register | |

|

Dec 2-5, 2024 4-days |

(Click link above for event details) |

$1995 |

Register | |

|

June 9-12, 2025 4-days |

Idaho Falls, ID (Venue TBD) |

$2495 |

Register |